Enrolling in a CNC operator program in Connecticut is a great way to launch a career in CNC machining – a fast-paced, exciting field with a wide variety of day-to-day duties. Learn more!

Manufacturers in Connecticut are leaders in making products that are vital for the world, including jet engines, helicopters, submarines, and even medical devices. But thanks to technological advancements, gone are the days of the gritty factory life. Computerized numerical control (CNC) machinists combine elements of mechanical design, technical drawings, mathematics, and computer programming know-how – in a clean, professional environment – to produce these crucial products for our world today.

Those pursuing CNC operator careers enjoy working in a hands-on, never-a-dull-moment, growing field. And those with CNC machinist careers in Connecticut earn an average salary of $64,366 – the highest average annual pay for manufacturing in the country! But what are those moment-to-moment duties really like for a CNC Machinist? If you’re thinking of pursuing a CNC machining program in CT, read on for some of the important duties that operators can expect to perform as part of their daily routines.

With proper CNC machining training, machinists produce a tremendous variety of manufactured goods and work with all kinds of materials, such as plastics and metals, to do so. CNC machinists hold a major role in Connecticut’s booming manufacturing industry. These skilled professionals see a product through each phase of its creation, from the start of an initial concept to a fully-realized item.

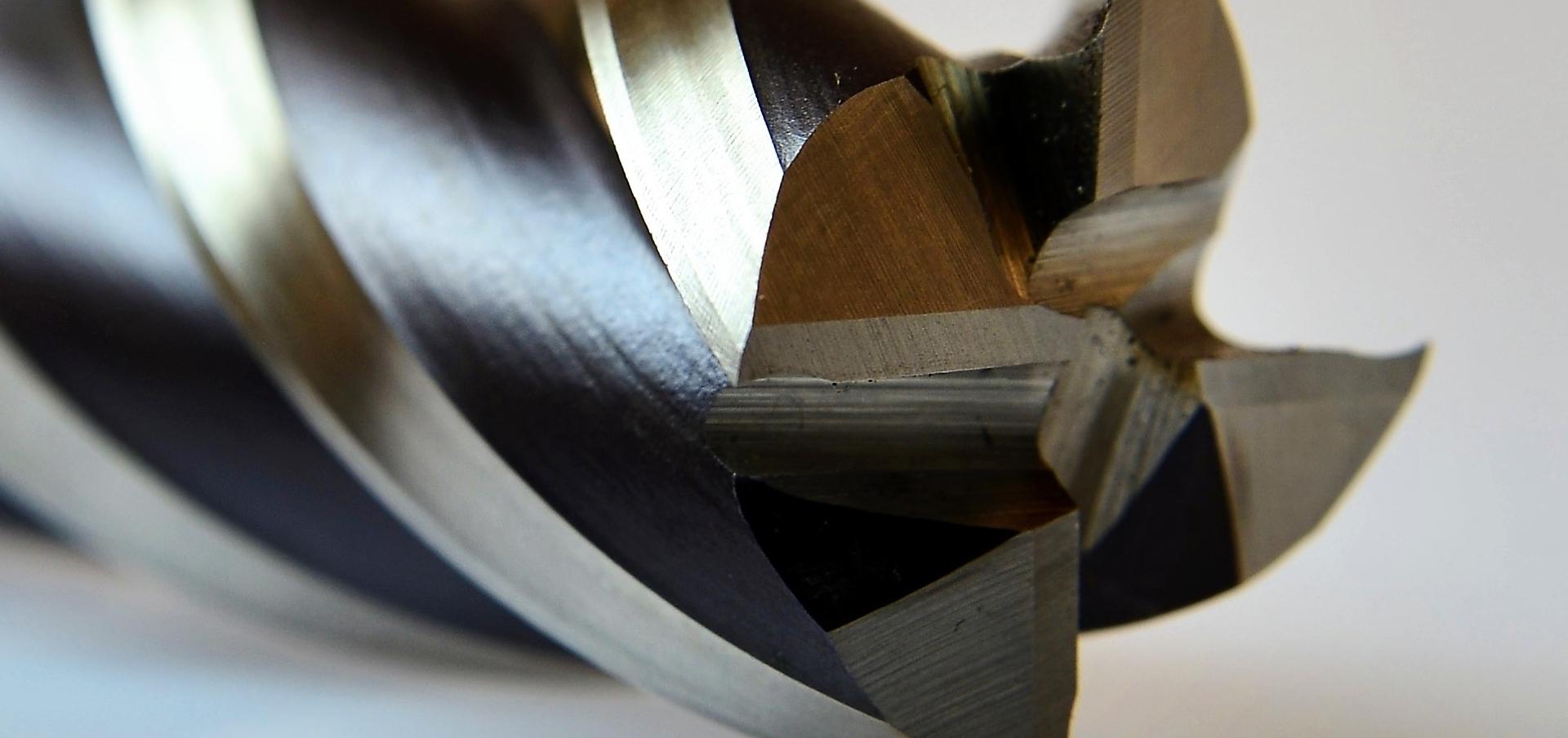

To put it into perspective, a CNC machine operator can transform a block of formless steel into a working part for one of the most advanced aerospace industries in the nation, using their hands, brains, and a dedicated set of CNC machinist skills. Typical daily duties for CNC operators include:

- Reading blueprints, sketches, or computer-aided design (CAD) and computer-aided manufacturing (CAM) files to determine the specs and tolerances of a product

- Setting up, operating, and disassembling manual, automatic, and computer numerically controlled (CNC) machine tools

- Aligning, securing, and adjusting cutting tools and workpieces

- Monitoring the feed and speed of machines

- Turning, milling, drilling, shaping, and grinding machine parts to specifications

- Measuring, examining, and testing completed products for defects

- Smoothing the surfaces of parts or products

- Presenting finished workpieces to customers and make modifications if needed

In addition to a great salary, those interested in a CNC operator career can look forward to a flourishing field with plenty of job opportunities. The Bureau of Labor Statistics expects employment of machinists to be good because the number of job openings from year-to-year will continue to hold steady, as workers retire or leave the occupation. In Connecticut, the job outlook for CNC machinists is even more great. According to the Connecticut Department of Labor, employment of CNC machinists is expected to grow 23 percent by the year 2024, with about 141 CNC machinist careers opening up each year.

For those looking to join an exciting and growing field, earning an associate degree and/or certification from a career-focused manufacturing school in Connecticut is a great investment in the future! Goodwin College’s competitive CNC Machining programs are designed to get students licensed and working in the field in a very short period of time. Whether you’re looking to break into a CNC operator career or are already working in manufacturing, Goodwin College can help you advance your skills, training, and your career in this thriving field.

If you would like to learn more about a career as a CNC machine operator, call Goodwin College today at 1-800-889-3282 or explore our CNC Operator School online!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.