From airplanes and spacecraft to military equipment and high-tech electronics, modern manufacturing demands extreme precision. The ability to take raw materials and transform them into complex and functional components is both impressive and essential.

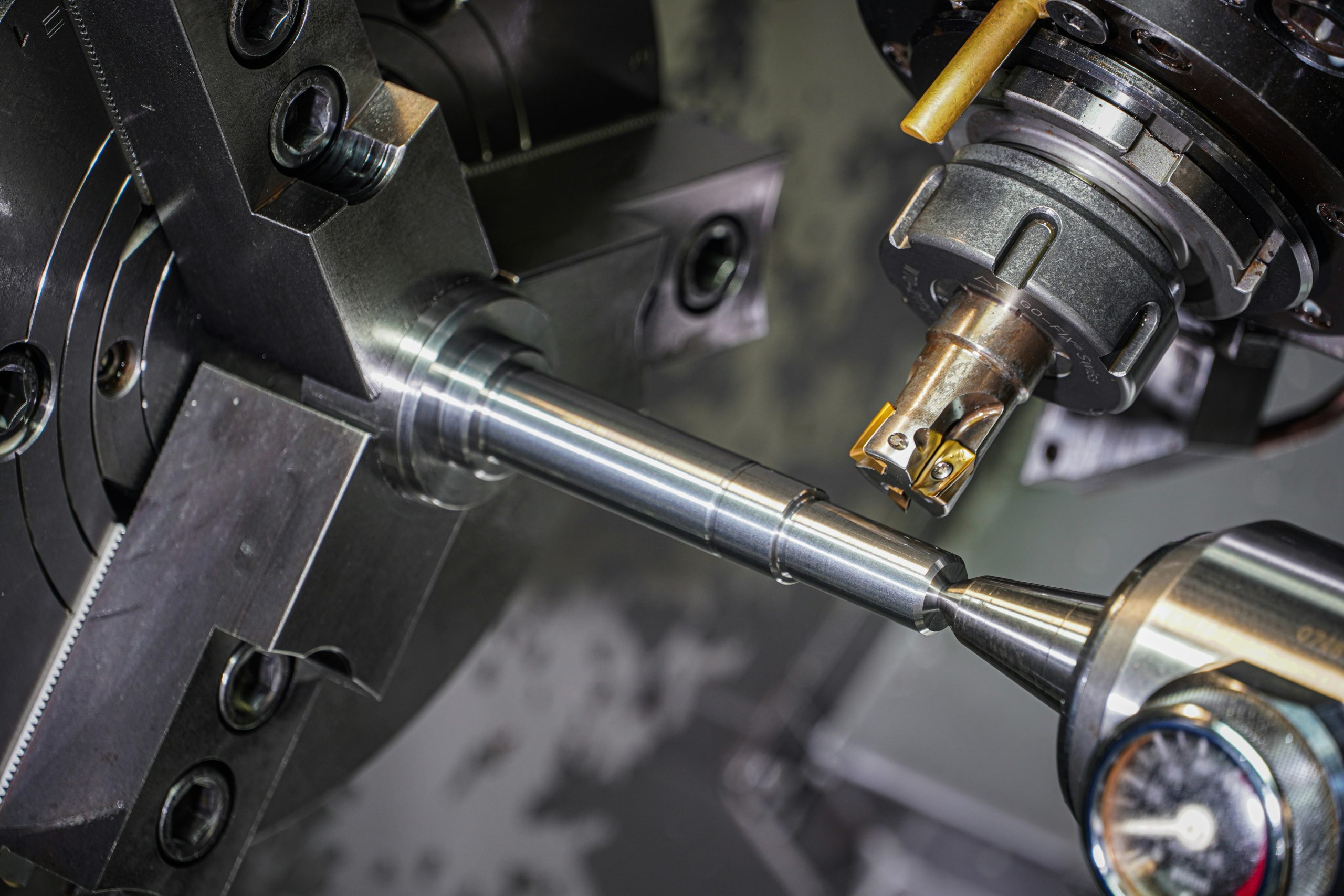

That’s why Computer Numerical Control, or CNC, Machining has become such a cornerstone of manufacturing.

CNC machining streamlines production like nothing else. Combining computer programming with physical machinery, it lets manufacturers create complex parts accurately and efficiently at high speeds. And within the field, there are multiple CNC machining techniques you can master—each with its purpose and strengths.

Maybe you’re curious about how modern manufacturing works. Maybe you’re thinking of pursuing a career in CNC machining. Or perhaps you want to become a jack-of-all-trades who can handle multiple manufacturing and CNC techniques.

Whatever your goal, understanding these seven CNC machining techniques is a perfect place to start. Manufacturing schools like Goodwin University offer hands-on programs designed to teach you the skills and knowledge you need to succeed in this ever-evolving, always forward-thinking industry.

What is CNC machining, and how is it done?

At its core, CNC machining is a manufacturing process where pre-programmed computer software directs factory machines on what to do. It turns once tedious tasks like 3D cutting into a few steps.

CNC machining starts with computer-aided design (CAD) software. Technicians and engineers create a 3D blueprint of what needs to be made. Then, that blueprint is turned into a file readable by the CNC machine. The file tells the machine exactly how to work with the materials it will be given.

Finally, once the machine is prepped, it builds the part based on the CAD instructions. With programmed instructions, every finished piece matches the design with a level of accuracy that’s nearly impossible to achieve by hand.

7 unique CNC machining techniques to master

With CNC machining, there isn’t just a single way to craft parts. Really, it’s a collection of techniques. Each technique has a purpose, and skilled machinists combine them for advanced parts. Here are seven CNC machining techniques that you’ll come across in a reputable training program.

1. Milling

Milling uses spinning tools to cut and shape materials. The tools are powerful and fast, spinning at a thousand rotations a minute. Unlike other processes, your materials feed into the tool rather than the tool moving into the material.

Milling allows unparalleled control compared to other techniques. It lets operators remove large excess material and make subtle cuts. Because of its versatility, CNC programming for milling is challenging and usually reserved for highly skilled CNC operators. Specific and specialized classes are needed to master it.

Mastering milling allows you to step into advanced manufacturing roles and specialized engineering projects.

Develop advanced machining techniques at Goodwin!

2. Turning

Turning uses a stationary cutting tool to trim extra material from a rotating workpiece held in a lathe. This technique is perfect for making simple shapes like rods, cones, and spheres.

While turning may be less controlled than milling, it is extremely practical for high-volume production. If you need consistency in a part or product, most machining turns to turning. You learn this technique so you can handle both bulk tasks and special orders.

3. Drilling

Drilling is one of the simplest CNC machining techniques, using drill bits to create precise holes and remove excess material. You can think of it like a mechanized version of your typical hand-held power drill.

While it is easy enough to pick up, drilling does take skill to get depth and alignment down correctly. It’s not just poking holes in materials and calling it a day. That said, the simplicity of drilling makes it a CNC machinist’s toolkit staple.

4. Grinding

Grinding uses a rotating grinding wheel to shape a piece and give it smooth surfaces. Unlike milling, grinding does not involve cutting tools. Instead, materials are removed through scraping and abrasion. You can compare it to sanding down edges or sharpening knives.

This technique is slower than the others in this list, but it’s essential in the finishing processes. Proper grinding makes sure that parts fit perfectly and properly function when and how they need to.

5. Electrical Discharge Machining (EDM)

Also known as “spark machining,” EDM uses electric sparks to sculpt metal without cutting it at all. There are two main types of EDM: wire EDM, which uses a wire to guide sparks, and die-sink EDM, which cuts with shaped electrodes.

EDM is perfect for materials that can’t handle manual cutting techniques. While time-consuming, electrical discharge machining is invaluable for detailed parts.

6. Sawing

You can call it the “old reliable” of CNC machining techniques. Like a regular saw, it involves taking a toothed blade and cutting through material to separate it into smaller pieces or specific shapes.

It’s as simple as it sounds, and it’s brought to the next level by CNC machining. CNC-controlled sawing guarantees the same part every time, making it perfect for rough cuts before the final touches and excellent for mass manufacturing.

7. Finishing

Finishing is, as it sounds, the final step in CNC machining, where most techniques you’ve learned come together. This part goes beyond the initial shaping to make it look nice and ensure it’s up to snuff. This is where finishing touches go, like final polishing.

Proper finishing ensures an accurate and sturdy finished product. Without it, even the most perfectly built machine could fail.

Learn CNC machining skills at Goodwin University

CNC machining is shaping the future of manufacturing as we know it. From the everyday objects we rely on to air and defense components, these techniques create what defines our modern life. More than ever, manufacturing needs skilled experts who know exactly how to operate and optimize these processes.

At Goodwin University, you have access to state-of-the-art equipment and expert instructors dedicated to hands-on learning. Our CNC training programs are designed to prepare you for any stage of learning, whether you want to become a CNC machinist or a jack-of-all-trades, mastering all the techniques you can.

If you’re ready to become part of the next generation of manufacturing innovators, the time is now. Learning CNC machining opens doors to high-demand careers using cutting-edge technology that literally builds our world.

Start your CNC machining journey at Goodwin University.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.