Technology has changed every industry, including manufacturing. Construction and manufacturing workers no longer solely work with hard hats and safety vests in the field.

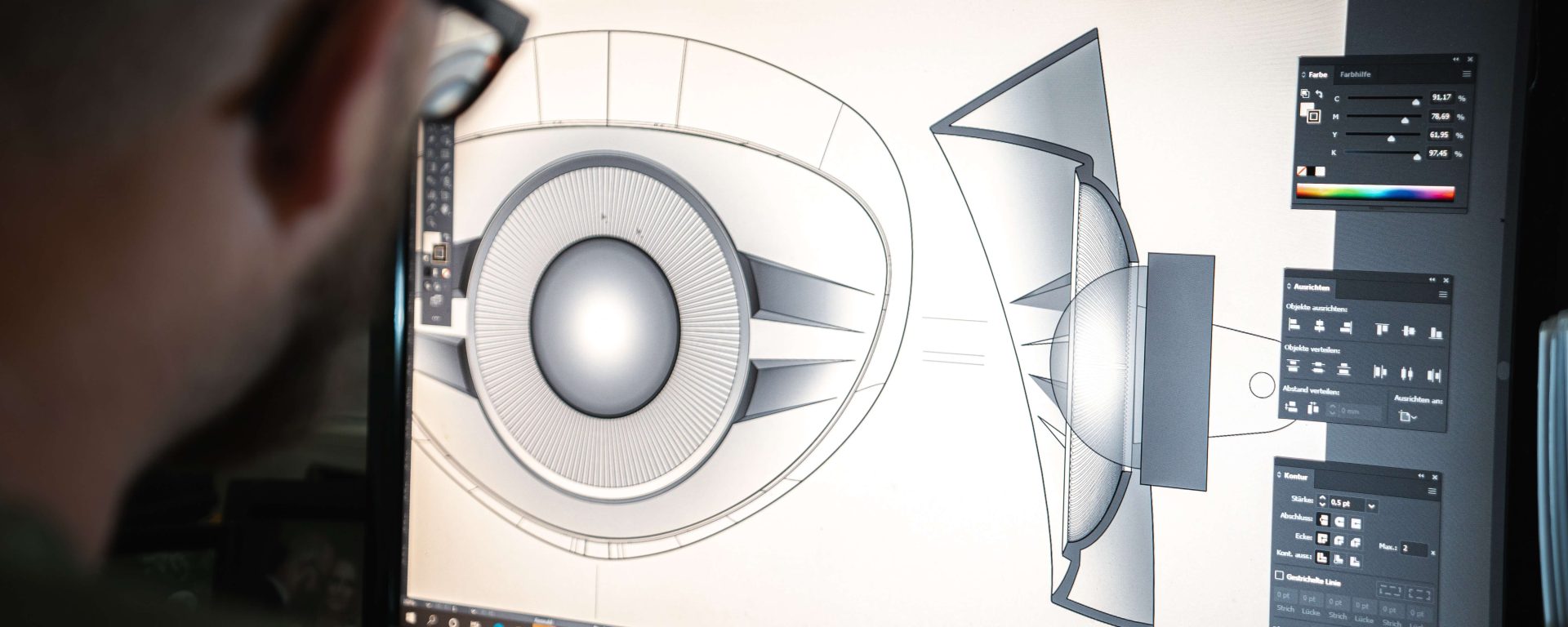

They also work inside, in front of computers, using cleaner, more efficient, and more accurate Computer-Aided Design (CAD) automated systems and programs. These streamline the process from initial ideas to two-dimensional and three-dimensional model designs.

Learning how to use this tool is now essential for manufacturing professionals, including architects, construction workers, and engineers. This article will discuss why Computer-Aided Design is essential, its influence on the manufacturing industry, and CAD technicians’ pivotal role on a manufacturing team.

What is Computer-Aided Design (CAD)?

Computer-aided design, often called CAD, is a manufacturing process that enables manufacturers to create 2D drawings or 3D models of future products digitally. This allows designers and engineers to visualize the product’s construction before fabricating it.

Instead of drawing and designing by hand, CAD has revolutionized the drafting process by using computers to develop, modify, and optimize product designs. Designs are now more detailed, accurate, and efficient using CAD software. Plus, professionals can adjust and optimize the designs and eventually manufacture goods more efficiently and intelligently.

Additionally, using CAD software allows designers to know how various materials will interact with one another, whether a design will ultimately work. Some advanced systems can help determine a product’s structural integrity and performance by simulating stress tests. Most CAD designs and software are available anywhere and accessible to entire production teams through this cloud-based technology.

Why is CAD Important?

There is no step more crucial to manufacturing an object or product than the technical drawing. It’s the point when the drawing must leave the engineer’s or designer’s oversight and become a reality, and it’s all based on what they drew.

CAD has become an invaluable tool, enabling engineers, architects, and other manufacturing professionals to produce easily understood and professional-looking designers faster.

1. Increased Productivity

As discussed, developers complete projects more quickly using CAD, cutting production costs. CAD designers seamlessly experiment with concepts and save drafts digitally through this efficient designing process.

This flexibility and ease of making changes in the drafting stage also enable designers and companies to create premium, affordable products and expedite production in all areas.

2. Reduces Errors

Unlike traditional design, once a design is finalized in CAD, zero manual input is required. This means that repetitive tasks, like symbol placements and drawing storage, are automated, and the risk of error is extremely low.

Additionally, this software is designed to forecast and prevent common design mistakes by alerting users of potential errors throughout the design process.

Other ways CAD helps prevent errors involve:

- Direct Design Transfer: Upon designing a product using CAD software, the designer can transfer the model directly to manufacturing equipment which crafts the item seamlessly, saving time and resources.

- Quick Prototyping: There is no longer a need for physical prototyping, as the designer can simulate all needed testing virtually in these programs.

- Easy Adjustments: Any changes, alternations, and adjustments in the various views can now be changed simultaneously in the production process.

3. High-Quality Products

While the risk for error is low, CAD is not an error-free process. However, the software allows designers to reference saved drafts and designs to address any potential or actual errors quickly and efficiently.

Designers can also predict errors before construction through low-risk, virtual investigation, allowing them and their organizations to improve manufacturing speeds and reduce resource waste overall.

4. Information Sharing

CAD programs catalog designs and changes to those designs in the cloud. This means that CAD files can be shared, analyzed, and reviewed with partners and teams to double-check details.

It also allows teams to collaborate on projects and fosters remotely improved communication through advances in:

- Internal information sharing

- Business-to-business interfacing

- Assembly line interaction

- Customer feedback

- Marketing and visualization efforts

What Does a CAD Technician Do?

Without CAD technicians, CAD software would be useless. It takes a skilled, qualified, and trained professional to use the software to convert designs into technical drawings that will ultimately be used to create products.

Designers and drafters don’t solely operate CAD software. They can also be responsible for designing products by engineering building techniques and specifying the size, materials, and procedures needed for development.

They are critical members of the manufacturing team in a variety of positions, industries, and fields, including:

- Architectural drafter

- Electrical drafter

- CAD technician

- CAD operator

- Engineering technician

- Interior design

- Aeronautics

- Automotive design

- Construction

- Medical and dental device manufacturing

Visit us online to learn more about how you can make your mark as a CAD Technician!

According to the U.S. Bureau of Labor Statistics, drafters make a median annual salary of $60,290, and an average of about 18,900 job openings are projected yearly until 2031.

Computer-aided design has carved the path toward exciting careers in various industries, especially for individuals passionate about design, engineering, or a cutting-edge, innovative career.

Candidates can complete a three-semester, eighteen-credit CAD certification program to jumpstart their careers. Students in our program learn how to design and measure 2-dimensional and 3-dimensional parts for manufacturing using Solidworks, Mastercam, and PC-DMIS.

Our program at Goodwin University has also enabled graduates to stand out from other CAD candidates as earning a certificate is a big selling point for prospective employers.

Learn more about our program by contacting us today. We are ready to help you enter the crucial, dynamic, and vital manufacturing industry as an expert in computer-aided design!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.