Unlocking your smartphone, starting your car, using a medical device, it all just works. We live in a world where things just work, but that reliability isn’t an accident. In fact, it’s the result of thousands of perfectly-measured parts fitting together, often barely a hair’s width between each other.

But what happens when those measurements are off? If a piston is a millimeter too wide, an entire line of engines comes to a stop. If an airplane part is just a centimeter too thin, that airplane is no longer safe. Any small measurement error leads to products failing, people being put at risk, and wasted time and parts.

Who stands between a perfect product and a manufacturing disaster? That’s where a metrology technician comes in. You might not have heard of it, but the role of a metrology technician is basically what holds modern manufacturing together. For those with an eye for detail and a mind for mechanics, keep reading for an exciting career option.

What is a metrology technician?

To understand the job, you first have to understand the science. Metrology is, simply, the science of measurement. It is the discipline of ensuring that one meter here is exactly the same as one meter anywhere else in the world.

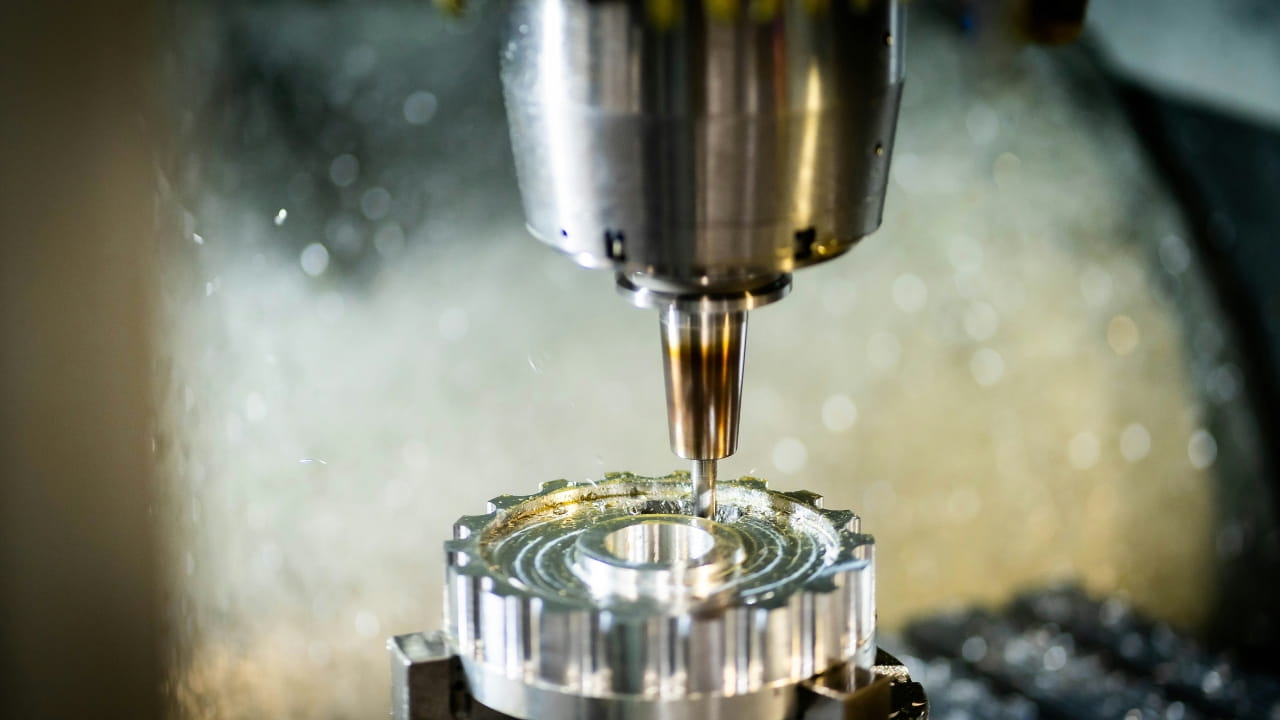

So, what is a metrology technician? They are the qualified professionals responsible for inspecting, testing, and calibrating the machinery and products that drive our economy. While engineers draft blueprints and machinists cut metal, the metrology technician serves as the ultimate quality assurance authority. They verify that the physical product matches the engineering design down to the micron.

If you enjoy working with technology and have a knack for precision, asking, “So, what is a metrology technician?” might be the first step toward your ideal career. It is a role that combines the hands-on nature of manufacturing with the intellectual rigor of data analysis and mathematics.

Core responsibilities of a metrology technician

If you asked a professional in the field, “What does a metrology technician do?” they’d tell you that no two days are the same. However, the job generally has four primary responsibilities.

Calibration

Tools wear out. Over time, the readings of measuring instruments can drift and become slightly inaccurate. A major part of the technician’s day is spent calibrating these instruments. Tools like micrometers and gauges are adjusted against a known standard to ensure they’re reading 100% accurately. If the ruler is wrong, everything it measures will be incorrect.

Inspection

Technicians use advanced technology, such as Coordinate Measuring Machines (CMM), to measure prototypes and final parts. A CMM uses a sensitive probe to touch points on an object, creating a 3D map of its dimensions. The technician programs and operates these machines to verify that complex parts meet the required specifications.

Data analysis

As well as making measurements, technicians also record detailed measurement data to spot trends. For example, they might notice that parts coming off a specific machine are slowly growing over a week. This data allows the team to fix the machine before it starts producing scrap parts.

Compliance

Industries like aerospace and defense are heavily regulated. A metrology technician ensures that all parts and processes meet strict industry standards, such as ISO regulations. They maintain the documentation that proves a product is safe and ready for use.

Where do they work?

When you think of manufacturing, you might picture a dark factory. However, for a metrology technician, the reality is quite different. Because temperature and humidity can expand or shrink metal parts, affecting measurements, metrology often takes place in climate-controlled labs known as “Clean Rooms.”

Compared to most machining jobs, this environment is cleaner, quieter, and more comfortable. In this setting, technicians support some of the most exciting and high-tech fields in the world, including:

- Aerospace: Verifying the geometry of turbine blades and aircraft fuselage parts.

- Automotive: Ensuring engine components and transmission gears mesh perfectly for efficiency.

- Medical device manufacturing: Inspecting life-saving surgical tools and orthopedic implants where precision is a matter of life and death

- Defense: validating components for military vehicles and equipment.

Get your Metrology certificate at Goodwin University today.

Key skills needed

While anyone with the right drive can learn the trade, successful technicians usually possess a specific blend of hard and soft skills. The equipment used in metrology is delicate and expensive, and facilities need professionals they can rely on to handle it correctly.

Hard skills

- Math: You don’t need to be a mathematician, but you do need a solid grasp of geometry and trigonometry to understand angles and dimensions.

- Blueprint reading and GD&T: A core skill is the ability to read complex blueprints and understand Geometric Dimensioning and Tolerancing (GD&T) — a symbolic language used to communicate engineering tolerances

- Computer skills: Since much of the inspection is done via CMMs and digital arms, computer proficiency for programming and data entry is essential

Soft skills

- Extreme attention to detail: In this field, close isn’t good enough — you need the patience to pursue perfection

- Problem-solving: When a part fails inspection, the technician often helps figure out why. Is it the material? The cutting tool? The fixture?

- Communication: You must be able to clearly explain your data to engineers and machinists, bridging the gap between design and production

How to get started in metrology

If you are interested in this career, you might be wondering about the barrier to entry. The good news is that you do not always need a four-year degree to start. The manufacturing industry values practical skills.

Employers are looking for candidates who know metrology but, more importantly, have hands-on experience with actual equipment. Luckily, certificate programs like Goodwin University’s accelerated CNC and Metrology certificate are explicitly designed for that. These programs focus on getting students into work quickly by emphasizing the core skills employers actually need from technicians.

Ready to learn metrology?

The question “What does a metrology technician do?” has a simple answer, though the role is quite complex. Metrology technicians measure parts to ensure our most critical devices don’t fail. So if you’re looking for a career that challenges your mind and rewards your precision, it is time to stop guessing about your future and start measuring it.

Get your Metrology certificate at Goodwin University today. In just over 22 weeks, you can gain the skills necessary to enter this dynamic field.

Master the science of measurement at Goodwin University.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.